With laser technology it is possible to realize a superficial heat treatment reaching high mechanical characteristics which are unthinkable to be obtained by other heat treatment processes. In addition to this peculiar features, laser technology offers numerous advantages over traditional technologies that make it a very interesting tool for the industrial world, especially today when the overcoming of classical limits of conventional processes and innovation of the production cycle can be decisive factors for increasing the competitiveness of a company.The advantages of using diode lasers for the surface heat treatment can be briefly summarized as follows:

- Obtaining high mechanical characteristics

- Distortion of the component is very limited if not absent

- Hardening done without hardening media (water, oil, salts, ...)

- Absence of pollution, dirt and smoke generation

- Reduced production cycle time of the component

The works carried out in laser heat treatment field are: basic and applied research, feasibility studies, consultancy and support

Some examples of the heat treatment applications studied with industrial collaborators are:

Heat treatment of construction steels:

The feasibility of heat treatment of torsional springs made of C40 to be used in automotive has been studied.

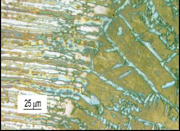

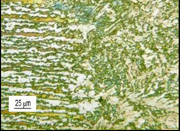

Heat treatment of martensitic stainless steel

Heat treatment of biphasic stainless steel:

The laser welding of stainless steel produces biphasic joints with a corrosion resistance much less than the base material. This makes necessary the post-weld heat treatment a necessity to restore corrosion resistance of the joint. At SITEC the possibility of heat treatment of the weld joint directly with a laser source located below the welding source has been verified with the result.

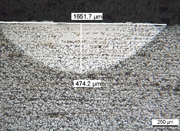

Heat treatment of cast irons:

Also grey cast irons with low wear resistance can be subjected to surface laser heat treatment to obtain very high surface hardness. Surface hardness value of 850 HV500 has been reached from the base hardness value of 200 HV500.

Dipartimento di Meccanica

POLITECNICO DI MILANO

Via G. La Masa 1

20156 Milano

Mail: segreteria.tecnologie@mecc.polimi.it