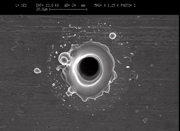

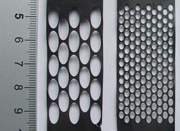

Laser micromachining allows obtaining structures with dimensions in micron range. It is performed with pulsed laser systems operating in different pulse width regimes namely nano, pico and femtosecond. The pulsed laser emission allows very fast ablation of materials with high peak powers. The very short pulse widths allow the process to become localized therefore the heat is not allowed to be dissipated inside the workpiece, reducing the heat affected areas. As the pulse width decreases even more, the process becomes all evaporation and melt free. Micro laser processes with ultrashort pulses are named to be cold processes.

The main laser micromachining processes on the other hand are microdrilling and microcutting. One of the main applications of laser micromachining is in biomedicine. Surface texturization of bio-implants, manufacturing of cardiovascular stents, and other medical equipment are some of the examples where the high precision and high quality parts are produced by laser micromachining processes. Manufacturing of photovoltaic cells is another field where micromachining is the dominant production method. High precision scribing of different layers are achieved by several micromachining steps. Electronics is another field where laser micromachining is used in the manufacturing of microchips and generating complex micro vias on circuit boards. In MEMS applications, where micro devices are produced, laser micromachining plays a key role. Other emerging fields are aerospace, microfluidics and marking.

The micromachining research field of SITEC is equipped with a 50 W IPG Photonics pulsed fiber laser system and a 100 W IPG Photonics continuous wave fiber laser system which can be externally pulsed. Main studies in this field are microdrilling and microcutting, in terms of their applicability to various materials such as advanced engineering materials, advanced coatings, and bioabsorbable materials, as well as study of process parameters, quality assessment and monitoring.

Dipartimento di Meccanica

POLITECNICO DI MILANO

Via G. La Masa 1

20156 Milano

Mail: segreteria.tecnologie@mecc.polimi.it