MONITORING AND CONTROL OF LASER PROCESS

Over the years SITEC has acquired extensive expertise in monitoring the quality, the characteristics, and the diagnosis of the process and the system and also has developed competencies regarding the control of different laser process.

Some solutions developed by SITEC are:

Through Optical Combiner Monitoring (TOCM) of Fiber Laser processes

In this research area, we have developed a new monitoring technique designed for high brilliance (fiber) laser processes named Through Optical Combiner Monitoring (TOCM).

This new monitoring solution for fiberlaser processes is now under development at SITEC and can be used in all the fiberlaser sources in which an optical combiner is present.

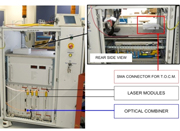

The optical combiner can be considered the core of a fiber laser source because it sums together the power coming from different laser modules and convoys it to the delivering fiber. In the TOCM solution we plugged an optical fiber to one of the free insertions of the combiner allowing an easy coaxial process monitoring with different equipment, mainly photodiodes benches, monochromators and spectroscopes.The TOCM solution shows some interesting advantages, such as the easy and non intrusive installation of the device in the system, an increased reliability of the device because none of its parts needs to be near the process but they are inside the laser source and, finally, the control of the monitoring device can be easily integrated and interfaced with the laser source management.

The first prototype of an IPG Photonics YLR laser source designed for the TOC monitoring has been installed by July 2007 at SITEC. The laser source is an YLR 1000 based on a two laser modules architecture (500 W each). A 50 µm core diameter fiber optics is coupled into a free slot ending with a common SMA-type connector, commonly used for easy plug in of optical instrumentation and devices.

Optical seam tracking device for laser welding process

This device permits to geometrically track a welding seam; a vision system similar to the human eye is used to acquire the seam and to send the information gathered to the laser source in order to perform the weld. In this way the track is no more upload in the NC, but is directly acquired by the machine. The system consists of an opportunely filtered video camera which acquires the geometry of the seam. The seam is at the same time enlightened by a diode laser which permits the correct view of the seam overcoming the disturbances coming from the process. The information gathered from the video camera are real-time elaborated by the dedicated vision-analysis algorithm. The digitalized track is send to the galvanometric mirror which deflects the laser beam making the seam tracking. The performance of the prototypal device allows to track seam with a maximum travelling speed of 3000 mm/min with a transversal resolution of 0,03 mm/pixel.

Temperature control during diode laser hardening

The prototypal pyrometric device allows the real-time measurement of the surface temperature of the work pierce during the laser heat treatment. This, together with the development of the respective algorithm permits the closed loop control of the diode laser hardening. Among the various applications in which the pyrometric device can be useful, the most important is the apparent spot circular laser hardening.

Dipartimento di Meccanica

POLITECNICO DI MILANO

Via G. La Masa 1

20156 Milano

Mail: segreteria.tecnologie@mecc.polimi.it